Innovative Manufacturing Technology

May 14, 2024

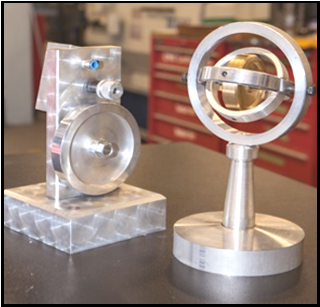

By definition, a Machinist is a skilled person who can manufacture components from technical drawings using precision measuring tools and a variety of machining tools. All aspects of society today depend on Machinists working in machine shops. All transportation is dependent on skilled Machinists. Consumer goods require Machinists to create plastic injection moulds and to build machines to manufacture consumer goods. When a part on something breaks or wears out a Machinist can build another. Innovative Manufacturing Technology at Tec-Voc is a manufacturing environment where students create a wide variety of parts usually from metal. You learn to use different machines and hand tools to shape metals into precision working parts while having fun! Students machine different projects for each course which they take home. Tec-Voc Machinists compete in the Skills Competition every year and there are always opportunities to work with other Tec-Voc classes and even other schools.

Grade 9 (.5 Credit) MEHR1G

This course is intended for students who wish to sample Machining Technology. Students develop skills and knowledge necessary to perform basic calculations, basic machine and work set-up, and basic cutting of material in a safe, efficient, and responsible manner through the application of practical projects. An appreciation for the machining program is fostered through a safe, active, exciting, and informative learning environment.

Grade 10 (1 Credit) MT841V1S

Students will learn an introduction to technical drawing interpretation, hand tools, layout techniques, drill press operation, band saw operation, precision measurement, lathe operation, quality control and computer numerical control (CNC) programming, set-up operation and more.

Grade 11 (4 Credits) MT000V30

Grade 11 (4 Credits) MT000V30

Students will learn safety, advanced technical drawing interpretation, advanced lathe operation, introduction to milling machines, advanced quality control and advanced CNC programming set up, operation and more.

Grade 12 (4 Credits) MT000V40

Students will have the opportunity to improve their skills on all machine shop equipment as well as advanced milling operation, expert advanced lathe operation, expert advanced CNC programming, set-up and operation. There is also opportunity for work experience during the year. Time is taken to prepare students for their transition from high school to work or post secondary education.

Innovative Manufacturing Technology Employment Opportunities:

Graduates from this program will have the required skills for employment in the following:

· Machinist

· Tool Maker

· CNC Programmer

· CNC Operator

· Aerospace Manufacturing

· Laser Machine Operator

· Quality Control Inspector

· Bus Manufacturing

· Farm Machinery Manufacturing

· Fabricator

· Machine Tools Sales

· Machine Tool Service

· Engineer

· Engineer

· Teaching

Innovative Manufacturing Technology is a program that can be very helpful for the students pursuing a post secondary education in the fields of Engineering, Mechanical Drafting, Aerospace, Welding, Automotive Fabrication and more.

As an accredited program, students who complete and maintain an average of 70% can greatly reduce the length of their Machinist apprenticeship. Upon graduation/program completion they will receive the theory component of a level 1 Apprenticeship status in Machining and can immediately begin their career in the Machining industry upon finding suitable employment. Please contact us for complete information on our apprenticeship program.

Virtual Tour